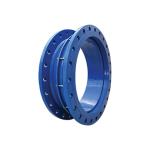

Dismantling Joint F1, F2, F3 | Durable Pipeline Solutions at Export

- Dismantling Joints (F1, F2, F3) are essential pipeline components used in water supply, wastewater, industrial, and power applications.

- They allow quick installation and removal of valves, pumps, and fittings, reducing downtime and maintenance costs.

- Manufactured from ST37-2 carbon steel or ductile iron with NBR/EPDM gaskets, they ensure durability and reliable sealing.

- Epoxy powder coating (≥250 µm) provides corrosion resistance and certification for safe drinking water use.

- Available in DN 50–3000 mm and PN 10–63 bar, they are offered at competitive export prices with global delivery support.

Exporting Dismantling Joint F1, F2, F3 at Competitive Prices

Dismantling Joints (F1, F2, F3) products are widely used in water transmission, municipal networks, industrial facilities, power plants, and desalination projects.

Our dismantling joints are designed for easy installation and removal of valves, pumps, and fittings. By shortening the dismantling length, operators can quickly replace or service equipment without disturbing the main pipeline, saving both time and maintenance costs.

With strict adherence to international standards and the use of premium raw materials, our dismantling joints deliver strength, durability, and reliable sealing performance. We offer them at very affordable export prices, helping buyers reduce procurement costs without compromising quality.

Technical Specifications

| Feature | Details |

|---|---|

| Product Name | Dismantling Joint (F1, F2, F3) |

| Nominal Diameter (DN) | 50 – 3000 mm |

| Pressure Rating (PN) | 10 – 63 bar |

| Design Type – F1 & F2 | Rigid type for easy dismantling of valves and fittings |

| Design Type – F3 | Non-rigid type: absorbs vibration, compensates angular deflection up to ±4° |

| Socket / Spigot / Mid. Ring | ST37-2 Carbon Steel or Ductile Iron |

| Gasket Material | NBR or EPDM |

| Bolts & Nuts | High-strength Galvanized Steel |

| Coating | Epoxy Powder Coating ≥ 250 µm, electrostatic application |

| Certification | Approved for drinking water use by recognized international institutes |

| Application Sectors | Water supply, wastewater, industrial processing, municipal networks, desalination, irrigation |

| Export Benefits | Competitive price, global shipping, customizable sizes, OEM support |

Why Choose Dismantling Joint F1, F2, F3?

- Ease of Installation and Removal: Quick dismantling reduces downtime during pipeline maintenance.

- Versatility: Available in DN 50–3000 mm and PN 10–63 bar for projects of any scale.

- High Durability: Made of ST37-2 carbon steel or ductile iron for long service life.

- Advanced Coating: Epoxy powder coating ensures corrosion resistance and drinking water safety.

- F3 Unique Design: Absorbs vibration, neutralizes misalignment, and tolerates higher pressure.

Export Advantages

- Affordable pricing compared to global suppliers.

- OEM and customization options for sizes, coatings, and packaging.

- Reliable supply chain with on-time global delivery.

- Compliant with international standards and certifications.

- Trusted in Middle East, Europe, Africa, Asia, and CIS markets.

Packaging and Shipping

- Standard export packaging with wooden pallets or crates for safe delivery.

- Customized labeling available for distributors.

- Bulk order discounts offered for wholesalers and contractors.

- Delivery terms include FOB, CIF, and DDP as per buyer requirements.

Key Benefits for Importers and Distributors

- Cost-effective pipeline solution with strong international demand.

- Designed for long service life and minimal maintenance.

- Certified epoxy coating ensures drinking water safety.

- Available in F1, F2, and F3 models for multiple applications.

- Supported with technical documentation and after-sales assistance.

Add your review

Your email address will not be published. Required fields are marked *

Please login to write review!

Looks like there are no reviews yet.

by Abrisham Road

Inspection group .co

Nahrab Gostar Tehran Company

- Store rating

0

- Staff

> 10

- Offers

> 100

- Products

19