Hammer Mill Machine | Industrial Metal Crusher | Best Export Prices

- Hammer Mill Machine is a high-performance industrial crusher designed for large-scale tin waste and metal recycling.

- It converts thin-sheet metals—like oil cans, soda cans, and beverage containers—into uniform, colorless pelletized iron and iron oxide.

- These pellets enhance smelting efficiency, reduce energy use, and increase overall metal recovery rates.

- Built to international export standards, it offers durability, low maintenance, customizable options, and competitive global pricing.

- With heavy-duty construction and continuous 24/7 operation capability, it is ideal for recycling plants seeking reliable, efficient metal processing.

Hammer Mill Machine for Export – Advanced Tin Waste Recycling & Metal Recovery

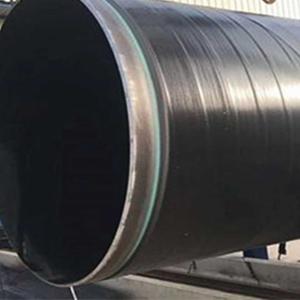

Hammer Mill Machine is a high-performance industrial crusher engineered for large-scale metal recycling and tin waste processing. Designed for converting thin-sheet metal scraps such as oil cans, soft drink cans, beverage bottles, and other tin containers, this machine produces uniform, colorless pelletized iron and iron oxide. These pellets significantly improve smelting efficiency and metal recovery rates in industrial applications.

Built with international export standards in mind, the Hammer Mill Machine offers exceptional durability, low maintenance, customizable configurations, and highly competitive pricing for global buyers in Asia, the Middle East, Africa, and Europe.

Comprehensive Product Description

The machine uses high-speed impact forces generated by rotating hammers to crush metal waste into dense, uniform pellets. Its specially designed crushing chamber removes color coatings and impurities, ensuring pure iron and iron oxide outputs suitable for smelting and steel recycling. Heavy-duty construction and reinforced steel housing ensure long operational life, even under continuous 24/7 industrial use.

Key Technical Advantages

- Processes large volumes of thin-sheet tin waste efficiently

- Produces uniform, colorless pellets with high purity

- Heavy-duty steel housing for maximum durability

- Energy-efficient motor for reduced operational costs

- Easy access for maintenance and rapid hammer replacement

- OEM and customization options available for export buyers

Technical & Commercial Analysis Table

| Category | Description / Specification |

|---|---|

| Machine Type | Industrial Hammer Mill – Tin Waste Recycling System |

| Primary Function | Crushing and pelletizing tin waste and thin-sheet metals |

| Applicable Waste Types | Oil cans, soda cans, soft drink bottles, tin containers |

| Output Material | Colorless pelletized iron and iron oxide |

| Output Uniformity | High consistency; ideal for smelting |

| Operating Mechanism | High-speed hammering and impact crushing |

| Hammer Material | Wear-resistant alloy steel |

| Screen Type | Replaceable screens for custom pellet sizes |

| Capacity Range | Medium to high capacity (customizable) |

| Motor Power Options | 30 HP – 150 HP (depending on buyer needs) |

| Energy Consumption | Optimized for low power usage |

| Operational Mode | Continuous 24/7 functionality |

| Safety Features | Overload protection, vibration reduction |

| Control System | Manual or semi-automatic control panel |

| Maintenance Level | Low maintenance; quick hammer replacement |

| Machine Body Material | High-strength steel with anti-rust coating |

| Export Packaging | Wooden crate or metal-frame industrial packaging |

| OEM Options | Custom color, logo, motor brand, and capacity |

| Ideal Buyers | Recycling factories, scrap yards, metal processing plants |

| Pricing | Export competitive (FOB/CIF/CFR based on destination) |

| Warranty | 12 months standard, extendable upon request |

Commercial Advantages for Global Buyers

- High return on investment due to efficient metal recovery

- Suitable for large-scale metal recycling operations

- Long-term durability with reduced maintenance costs

- Strong demand across international recycling markets

- Customized engineering options for buyer-specific requirements

Extended Marketing Description

Upgrade your industrial recycling capacity with our Hammer Mill Machine, engineered for heavy-duty tin waste crushing and iron pellet production. This system is ideal for transforming metal scrap into valuable, clean, and uniform pellets that support smelting and steel production. With its strong structure, consistent performance, and export-friendly pricing, it is an essential machine for metal recycling plants worldwide.

Add your review

Your email address will not be published. Required fields are marked *

Please login to write review!

Looks like there are no reviews yet.

by Abrisham Road

Inspection group .co

Majan Sanaat

- Store rating

0

- Staff

10

- Offers

> 100

- Products

3