Iran, a major Middle East producer of steel, cement, tiles, ceramics, and natural stones, exports to Central Asia. The A...

Iranian Building Stone Production Industry: Iran's Role in Global Construction & Economic Growth

The Process of Producing Building Stones

Iranian building stones from natural quarries to finished products involves several crucial steps: extraction, cutting, processing, and finishing. Each step requires precision, advanced technology, and adherence to environmental standards to meet market demands and ensure quality.

1. Stone Extraction: The Foundation of the Industry

Building stones are extracted from natural quarries using various methods. The type of stone—whether granite, marble, travertine, sandstone, or limestone—determines the extraction technique.

- Advanced Tools: Modern equipment such as wire saws, diamond-tipped drills, and controlled blasting are employed to extract large blocks of stone with minimal damage.

- Environmental Considerations: Sustainable extraction practices, including reducing waste and minimizing ecological impact, are becoming increasingly important.

- Product Quality: Stones are carefully selected to ensure they are free of cracks, voids, or other defects that may compromise their integrity.

2. Stone Cutting: Transforming Raw Blocks into Usable Pieces

After extraction, stones are transported to factories for cutting. High-precision tools such as disc saws, CNC machines, and laser cutters allow for intricate designs and optimal material utilization.

- Cutting techniques vary based on stone hardness.

- Customization options for size and shape cater to diverse architectural needs.

- Waste management systems ensure efficient use of raw materials.

3. Stone Processing: Enhancing Durability and Aesthetics

Processing involves multiple stages to enhance the stone’s appearance, strength, and usability.

- Polishing: To achieve a glossy, mirror-like surface.

- Resin Coating: To fill cracks and increase structural integrity.

- Waterproofing: To enhance resistance against moisture and weathering.

- Thermal Treatment: To improve the stone’s resistance to temperature fluctuations.

4. Stone Finishing: Preparing for Market

Finishing is the final step before the stones are delivered to the market. Techniques include honing for a smooth matte surface, flaming for a textured appearance, and sandblasting for slip resistance.

Types of Building Stones

Building stones are categorized into natural and artificial types, each offering unique characteristics that cater to different applications and preferences.

Natural Stones:

- Granite: Known for its exceptional strength and resistance to pressure, granite is widely used for exterior façades, flooring, and countertops.

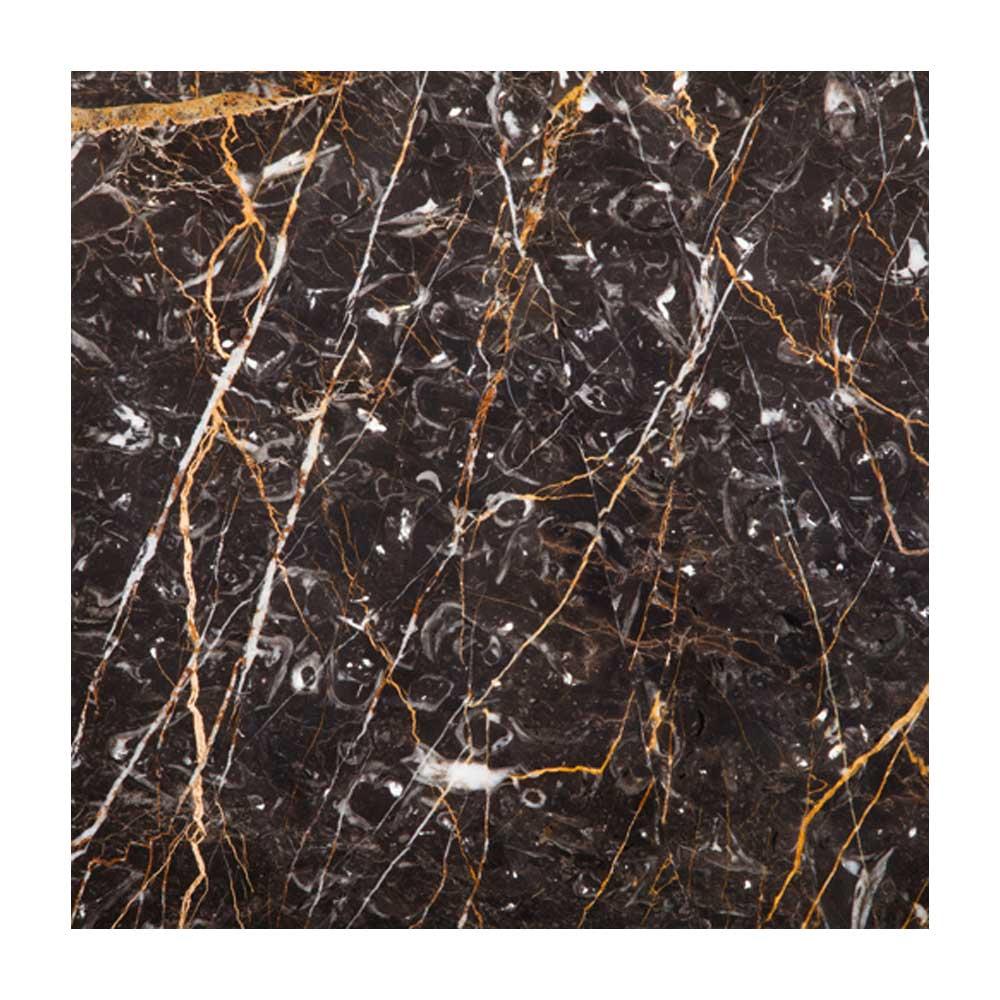

- Marble: Renowned for its elegance and natural veining, marble is a favorite for interior decoration and luxury projects.

- Travertine: Popular for its weather resistance and aesthetic appeal, travertine is commonly used in exterior façades and flooring.

- Sandstone: Often employed in landscaping and outdoor spaces, sandstone offers durability and a unique texture.

Artificial Stones:

Artificial stones, crafted from a blend of natural stone fragments and synthetic materials, provide cost-effective alternatives with a wide variety of colors, patterns, and finishes.

Applications of Building Stones

Building stones have a wide range of applications in construction and design. Their versatility makes them indispensable for various projects:

- Building Façades: Travertine and granite are commonly used for exterior walls due to their durability and aesthetic appeal.

- Flooring and Wall Cladding: Marble and limestone are popular for their elegance and smooth finish.

- Paving Streets and Public Spaces: Granite and sandstone are used for their resilience and slip resistance.

- Interior Design: Countertops, tables, staircases, and decorative elements often incorporate high-quality stones.

The Status of the Stone Industry in Iran

Iran’s rich geological resources and skilled workforce make it a global leader in building stone production. With approximately 8 to 15 million tons of stone produced annually, Iran has become a hub for high-quality natural stones.

Key Features of Iran’s Stone Industry:

- Diverse Quarries: Iran’s quarries produce a wide range of stones, including marble, travertine, granite, and onyx.

- High Domestic Consumption: A significant portion of the produced stones is used in Iran’s booming construction industry.

- Extensive Exports: Iranian stones are exported to over 100 countries, including China, Italy, Turkey, India, and the UAE.

Challenges:

- Outdated machinery and lack of modern technology in some quarries.

- High transportation costs and logistical barriers.

- Environmental concerns related to quarrying practices.

Growth Opportunities:

- By modernizing equipment and adopting advanced techniques, Iran can increase production capacity to 30 million tons annually.

- Developing eco-friendly products and expanding into artificial stone production can attract new markets.

Global Market and Demand for Building Stones

The demand for building stones is on the rise globally, driven by urbanization, infrastructure development, and luxury construction projects.

Top Importing Countries:

- China: The largest importer of raw stones, processing them for domestic use and re-export.

- Italy: A leader in stone processing and export, importing raw materials to meet global demand.

- UAE: With its rapid urban development, the UAE has a high demand for premium stones.

- USA: A significant market for processed stones, particularly marble and granite.

Advantages of Using Building Stones

- Durability: Stones are resistant to impact, pressure, and weathering, ensuring long-lasting performance.

- Aesthetic Appeal: The natural beauty of stones adds elegance and sophistication to any project.

- Versatility: Suitable for a wide range of applications, from structural components to decorative features.

- Eco-Friendly: Stones are recyclable and have a lower carbon footprint compared to synthetic materials.

Challenges and the Future of the Building Stone Industry

Despite its significance, the building stone industry faces several challenges that need to be addressed to sustain growth and competitiveness.

Challenges:

- High Costs: The extraction, processing, and transportation of stones can be expensive.

- Technological Gaps: Some regions lack access to modern machinery and techniques.

- Environmental Concerns: Quarrying and processing can have adverse effects on local ecosystems.

Future Prospects:

The future of the building stone industry looks promising, driven by technological advancements and sustainable practices. Key areas of growth include:

- Artificial Stones: Developing eco-friendly alternatives with enhanced properties.

- Export Expansion: Tapping into emerging markets and increasing global market share.

- Innovative Applications: Exploring new uses for building stones in industries such as art and furniture design.

Iran, with its rich resources and strategic location, is well-positioned to lead this growth. By investing in technology, sustainability, and marketing, the country can achieve its goal of increasing annual exports to $5 billion.

Conclusion

The building stone production industry is a cornerstone of economic development and construction innovation worldwide. Iran’s extensive reserves, high-quality stones, and skilled workforce place it among the top global players in this field. With strategic investments and a focus on sustainability, Iran can further strengthen its position in the global market, ensuring a brighter future for the industry and the economy.

For more detailed insights into specific types of stones, export opportunities, or technological advancements in the stone industry, feel free to reach out Abrishamroad.